Supplier in MAHARASHTRA

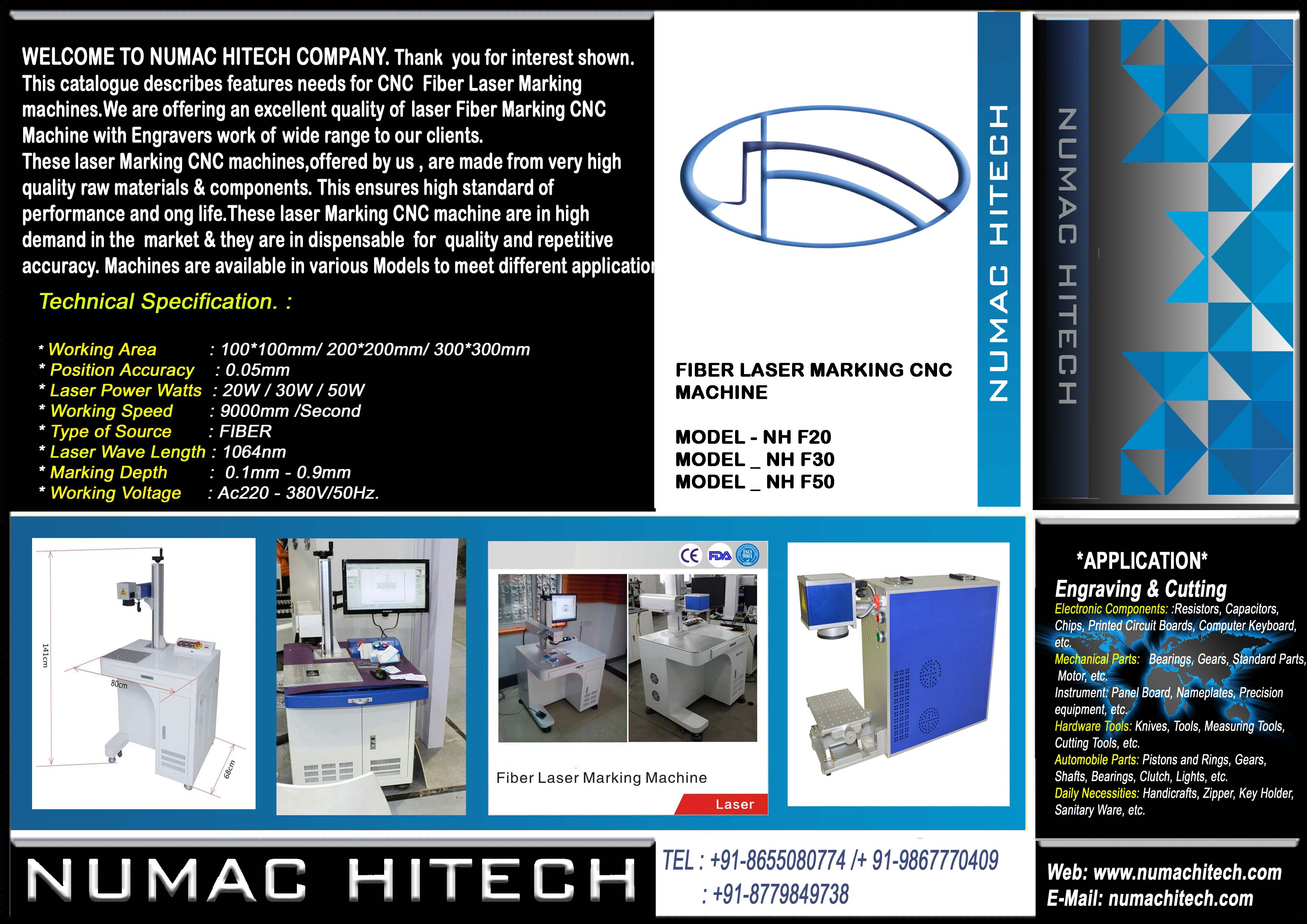

Fiber metal marking machines are advanced devices used for engraving or marking metals and other materials with high precision and speed. These machines are commonly used in industries like manufacturing, aerospace, automotive, and jewelry. Here are some key features of fiber metal marking machines:

1. High Precision and Accuracy

Laser Technology: Utilizes a fiber laser for precise and accurate markings.

Fine Details: Capable of producing very fine details, such as barcodes, serial numbers, and intricate designs.

2. Speed and Efficiency

High-Speed Marking: Can operate at high speeds without sacrificing quality.

Efficiency: Reduces marking time, which increases overall productivity.

3. Versatility

Material Compatibility: Can mark a wide range of materials including metals (steel, aluminum, gold, silver), plastics, and more.

Variety of Applications: Used for engraving, etching, and marking various items like tools, components, jewelry, and medical devices.

4. Durability and Low Maintenance

Long Lifespan: Fiber lasers have a long operational life, often exceeding 100, 000 hours.

Minimal Maintenance: Requires little maintenance due to the robust and stable design.

5. Non-Contact Process

Non-Intrusive Marking: The laser marking process does not physically touch the material, reducing the risk of damage.

High-Quality Marks: Produces high-contrast, permanent marks without distorting the material.

6. Computer Control and Automation

Software Integration: Comes with specialized software for designing and controlling the marking process.

Automation: Can be integrated into automated production lines for continuous operation.

7. Eco-Friendly

No Consumables: Unlike other marking methods, it doesn’t require inks, chemicals, or other consumables.

Energy Efficiency: Consumes less power compared to other types of marking machines.

8. Customizability

Adjustable Settings: Offers various settings for adjusting the marking depth, speed, and intensity.

3D Marking: Some advanced machines can perform 3D marking on curved surfaces.

9. Compact and Portable Design

Small Footprint: Many models are compact and suitable for various workspace sizes.

Portability: Some units are portable, making them easy to move between workstations.

10. Safety Features

Enclosures and Shields: Often equipped with safety enclosures to protect the operator from laser exposure.

Safety Interlocks: Includes safety mechanisms to prevent accidental operation.

These features make fiber metal marking machines an essential tool in industries requiring precise, efficient, and durable marking solutions.

Keywords

less power

wide range

3D Marking

Many models

high speeds

other types

fiber laser

key features

Fine Details

marking time

stable design

various items

Long Lifespan

marking depth

100, 000 hours

essential tool

No Consumables

serial numbers

high precision

laser exposure

Safety Features

other materials

Small Footprint

Portable Design

curved surfaces

Low Maintenance

medical devices

Computer Control

advanced devices

various settings

Energy Efficiency

safety enclosures

safety mechanisms

Safety Interlocks

intricate designs

accurate markings

other consumables

advanced machines

little maintenance

High-Quality Marks

High-Speed Marking

Adjustable Settings

Minimal Maintenance

Non-Contact Process

accidental operation

continuous operation

specialized software

Software Integration

overall productivity

Non-Intrusive Marking

laser marking process

other marking methods

long operational life

Material Compatibility

various workspace sizes

Accuracy Laser Technology

durable marking solutions

automated production lines

Fiber metal marking machines

high-contrast, permanent marks